This is a slightly more in depth look into the realities and legalities of using surplus TETRA kit in the united Kingdom. This deals ONLY with commercial use and not use by Radio Amateurs. Much of this applies to HAM use but there are a few exceptions where you CAN use these radios. However as is made clear in your licence you may not do so for commercial use.

The information in here is sourced either from other sites (I’ll try and link these in) or direct from OFCOM. Remeber before trying to argue the toss that it is actually OFCOM that has the final say.

And of course the caveat. I am not a lawyer, I don’t know your kit, I don’t know where it came from or how you intend to use it. This is a GUIDE only and nothing more. At the end of the day it is your responsibility alone, not mine, not the vendor who sold you the kit, to make sure what you are doing is legal and complies with the terms of your licence.

A little about licences…

In the original post I didn’t cover this at all, this lead to some confusion. You’ll likeley already have a business licence or be thinking about one. You’ll be looking at one of a number of options…

* Simple Light

* Simple Site

* Technically Assigned

* Area Defined

Suppliers Light is a very different kettle of fish but as a rule it doesnt get around the limitations discussed here. It buys you some more wiggle room but there are other restrictions.

Technically assigned and Area defined have changed a little and are seriously expensive if you start going mad. For the purpose of this I’ll be concentrating on the first two, that’s what the majority have and to be fair, if you have THAT much money to throw around on technically assigned or area defined there are some more avenues open to you.

There is one other avenue that makes this whole article moot. It is possible to obtain permission to access the Airwave network. For emergency organisations you may apply as a few have done including The Red Cross. However as a commercial entity allow a suitably large sum for network access and then per handset. It’s unknown if Airwave allow the use of your own equipment.

Your licence will give you more guidance, however typically you’ll get the following conditions: (Ive omitted bands that are of no interest)

Simple Light (Or just Simple)

Maximum ERP of 5W

No use of Base Stations

5 Allocations in the Low band (77.6875 – 86.3750)

7 Allocations in the VHF Band (164.0500 – 173.0875)

3 Allocations in the UHF Band (449.1325 – 449.4750)

Simple Site

Maximum ERP of 2W

Use of Base stations subject to above ERP Limit

16 Allocations in the VHF Band limited to .02W (159.63750-164.2000)

17 Allocations in the UHF Band (459.0500 to 459.47500)

Licence Free Bands

There is also a licence free band called PMR466 we need to bear in mind. The controls on what is allowed in this band are very strict. The band runs from 446.000 to 446.200 as twelve channels and another groups below this at 434.040 to 434.790. The requirements for this are availabe in some detail here, but one thing for our purposes is very important; “PMR446 users are reminded that their radios are only licence-exempt if they are built and operated within the conditions of the exemption regulations.” So this automatically rules out the use of ANY TETRA handset in this band. That was easy, no ifs, buts, just don’t! The details on this are here

Tetra Bands

Sepura and Simoco, the guys that started this decided that rather than this messy LF/HF/VLF/UHF/VHF mess they would use a simple two letter identifier to identify what bands their devices can use. If you check the model of your radio online it’ll give you what the capabilities are. You can sometimes also identify this from the hardware code where it’ll be the forth and fifth letters. The bands are as follows:

TG – 400-433Mhz

TL – 368-400Mhz

TN – 380-414Mhz

TR – 350-372Mhz

UO – 440-473Mhz

XB – 851-870Mhz

TZ – 410-430Mhz

TS – 370-400Mhz

TW – 380-430Mhz

TT – 380-400Mhz

UW – 407.473Mhz

So a quick look and we can write most ot his lot off right away. The Lowest we are realistically going to go on our licences is 449MHz. This means we are looking at UO or UW. Hams can in theory get away on the extreme edge of TZ and TW and a Technically assigned is possible to, but this is the extreme limit of the radio and a bad idea.

This is where it starts to really go wrong. Let’s look at what lives in those bands, you can look yourself here.

368-406 is pretty much all MOD, you REALLY don’t want to be in here!

406-430 is a mixed bag but mostly MOD.

UK Airwave allocation starts at about 380Mhz up to around 410. Dolphin had allocations in 425-430 and there are some D700 and D1700s still kicking about! All of this is in MOD space and “leased” to Airwave.

430 is Amateur (70cm) band. You don’t want to be here, if anything if you start upsetting Amateurs you are MORE likely to get caught!

There are more Tetra channels splattered about above here used by Connect (TFL) then into the licenced bands above. PMR466 on top and then we run out of band for all but XB. For giggles, XB is mostly pagers and Mobile phones.

So frequency wise, you have UO and UW as your options. The use of ANYTHING else simply isnt legal. UW sets are few and far between, I’ve never even seen a UO set. Almost everything on the market is TZ or TW and there is no way you can legally use these, no way, no how UNLESS you have specific permission from Airwave or Connect.

Caveat – As mentioned there ARE some Technically assigned frequences around 430Mhz, these are limited, first come first serve and expensive. You are also right on the radio’s limit so it’s really not recommended.

UK Back to back, DMO, TG1, Licence Free ETC

We’ve seen these mentioned a few times by sellers implying that you can use the radios they are selling exempt. The only exempt band in range of the frequency sets we have found legal to use specifically forbids the use of equipment not specifically designed for it. Even if it didnt the power of most TETRA sets is way over the allowed limit and they breach the band use conditions in other ways. Simply put, there is NO WAY to use these licence free.

Why Bother?

So you have found some UO/UW sets, you are thinking about buying them, why?! There is no good use case for these on the licences we have covered. If we assume you have a Simple licence you can’t have base stations, that in itself removes the big reason for using TETRA handsets.

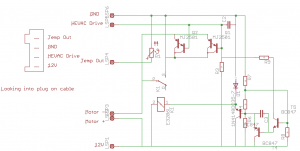

The handsets are designed to be used in range or a repeater in a vehicle or reasonable range of a relay/base unit. These are scattered all over the country and the radios can use any nearby vehicle base to jump onto the network. This leads to the second issue. You cant use any bases or repeaters so you are stuck with the handset’s output. Looking at one of the most common radios, the MTH800 we run into an issue. The rated power of this radio tops out at 1.8W with most running at just 1W. Although thats in the realms of your maximum for a Simple Site licence its significantly less than you can do on a Simple Licence. A quick search throws up ONE UW handset, the STP8040 which likewise tops out at 1.8W at £250 + £30 shipping from overseas. In comparison a good DMR (Motorola) can be had for under £100 from the UK and gives you 5W of RF power and the same security or more. Without a TEA module you can’t use the encryption feature of the handsets, that means your voice is transmitted as PCM data which is trivial to recover with a £30 USB dongle and a laptop. Most DMR radios CAN encrypt data properly.

Finally TETRA is built around the ability to pass data around the network, trunk out to the phone network and proivide many other features you just cant use without a full blown network, it’s not JUST a radio system. The use case for these is poor to say the least. In fact for the cost of that one handset you could have four good quality, solid analog units.

DCS/DMO/CTCSS and TETRA

Tetra and its relative MPT1327 assume exclusive use of a channel. The systems work differently but neither of them play well with other channel users. As part of your licence you have a duty to minimise disruption and the use of CTCSS, DCS or DMR codes is mandatory. We routineley run into whole swathes of spectrum rendered unsuable due to people not doing this. Where the majority of your transmission is data (as is the case with both) you’ll often cause the decoders on on the radios of other users to open meaning they get a blast of your data. It also means your radios will be unable to mitigate a congested channel properly so as well as driving other users up the wall there is no gurantee your radios will even work (Especially true of the MPT1327 control channel)

Legalities of Sale

If you are selling a TETRA radio with an active TEA and valid Airwave programming you are comitting a criminal offence, one that is highly likeley going to result in jail time. Most of these devices are trackable and if they have registered on the airwave network then they know where it is already. If you happen to end up with one of these units as a result of a surplus stock purchase or auction you need to contact Airwave imediately. Turn the radio off and call them. In the event you find one laying about dial 101 and arrange to hand it in. Don’t be tempted to use it.

Things go a bit grey after this. OFCOM don’t care about the sale of these devices and by selling of buying one you arent committing any specific criminal offence although the guide linked below does open the question of aiding and abetting the committing of an offence. It would be questionable in the eyes of Trading Standards were you to sell one intending it to be used, especially if passed off as licence free or legal to use. OFCOM have ben quite open about working with Trading Standards on this issue. The best bet here is speak to OFCOM, if they can be used they should be able to tell you, if not your only real option is to sell them as non working film props or if you are lucky enough to have the right ones, to Radio Amateurs.

What’s the Risk?

First up there is the side effects of actually using these radios on frequencies you shouldn’t. There is the obvious risk that you may cause interference. For some users that is going to cause annoyance and disruption and will in time lead to the issue being referred to OFCOM. However in more serious cases you may disrupt the Airwave network or Military comms in the local area, the potential is there to cause serious damage or loss of life.

Secondly, a lot of this spectrum lies within the MOD’s remit. The MOD are notorious for their lack of sense of humour when it comes to their spectrum space. I personally have experienced this as a result of pointing a Band C doppler radar in the wrong direction. They are very proficient at tracking down the cause of issues and making it stop. This at the very least is going to involve you doing a LOT of explaining before the decision is made to charge you or hand you over to OFCOM. Disrupting Military coms is a very bad idea!

And Thirdly there is OFCOM. They are well aware this equipment is out there and being used illegally. Officially you are likely to be looking at a large fine and the loss of your equipment, often the fine is based on the amount of illegal kit in use. However there is no upper limit and up to two years jail time is also on the table. At the time of writing there have been three local seizures of non compliant TETRA Equipment with 5 digit fines involved.

You have been warned!

Links

OFCOM: Radio Spectrum and The Law

OFCOM: Business Radio Licencing